RC Ducted Fan Jets

Let's face it, most of us can't afford to fly RC jets powered by genuine turbine engines just like full scale jets, although they are pretty darn cool to watch!

Let's get back down to earth and discuss the next best thing, RC ducted fan jets. There are both electric and glow powered ducted fans available.

What exactly are ducted fans?

Ducted air fans consist of a fan inside of a tube. The fan can be powered by either an electric motor or a glow engine.

RC electric ducted fan jets are referred to as EDF RC Jets. Glow powered ducted fan jets are referred to as GDF RC jets (Glow Ducted Fans).

The "tube" of most RC ducted fans is the aircraft itself. Some EDF's have ducted fan units mounted under the wings or near the rear of the fuselage. But most have the ducted fans embedded in the fuselage.

The ducted fan jet shown above has a typical internal ducted fan. The fan pulls air into the front of the fuselage and pushes it out of the rear, much like a full scale just.

The tube prevents losses in thrust from the tips of the fan blades. This greatly increases the efficiency of RC ducted fans compared with conventional propellers.

RC ducted fans have shorter and more blades than conventional propellers. This allows them to run at much higher speeds.

Electric RC Ducted Fan Jets (EDF)

Battery and motor technology has come a long way over the past few years

allowing electric ducted fan jets to fly extremely fast and they're available at a very reasonable price.

E-Flite is my favorite simply because they do all the hard work by sizing the components for you. All you have to do is order their plane with the recommended fan unit and you're ready to burn up the skies!

Many of their jets are available as Bind N Fly which is even easier.

Let's take a closer look at how

these ducted fans actually work.

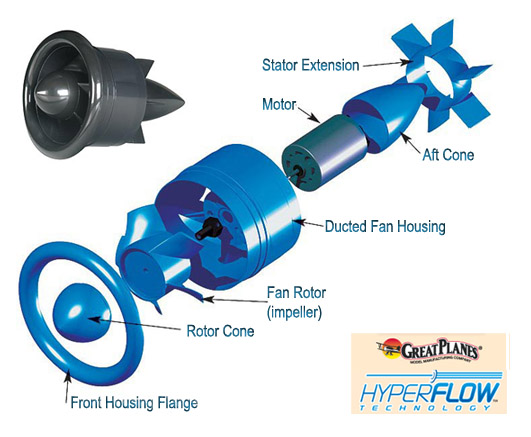

To understand the role of each component of an electric RC ducted fan jet, lets take a look at the image below. This is an image of Great Plane's Hyper Flow RC Ducted Fan Jet System.

Rotor Cone & Front Housing Flange:

The rotor cone and housing flange keep the airflow laminar, or smooth,

as it enters the fan. This increases the efficiency of the ducted fan

unit.

Fan Rotor:

The rotation of the fan rotor, or impeller, is what drives the air through the unit.

Housing:

The ducted fan housing is what contains and directs the airflow. The

profile or shape of this housing is critical to the efficiency of the

ducted fan.

Motor:

The motor is what provides the torque to turn the fan rotor.

Aft Cone:

The aft cone reduces or eliminates turbulence caused by the air passing over the motor or engine.

Stator:

When a fan is housed in a shroud, the rotation of the fan blades will

cause the air to move radially as well as axially. In other words, the

air will begin to flow in a vortex like a tornado. This rotation of the

air would cause turbulence which would reduce the efficiency of the

ducted air unit. Stators are stationary fan blades inside the housing

that straighten the air the air flow as it passes.

Glow Powered RC Ducted Fan Jets (GDF)

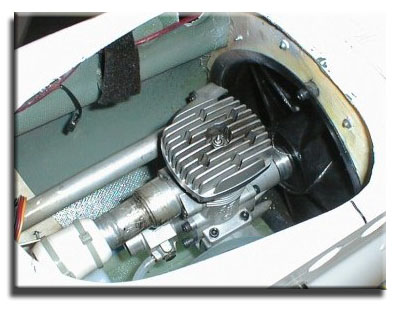

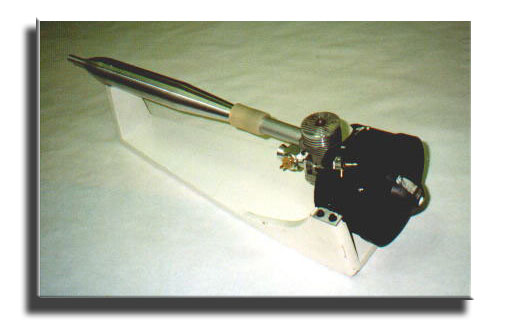

Glow ducted fans use glow engines specifically designed for driving a ducted fan. The image to the right is an OS .46 VX-DF with a Mac's tuned pipe used in conjunction with a Turbax 46 fan unit. The Turbax fan unit can be found at Jet Hangar Hobbies.

More examples of different types of tuned-pipes can be seen

below. As you can see, tuned pipes are used with land vehicles as well.

A tuned pipe is needed when using a glow engine with a ducted fan. The tuned pipe is that long tube you see extending from the engine. A tuned pipe basically pushes unused fuel from the exhaust back into the engine to increase the power.

The tuned pipe must be "tuned" to the maximum RPM by adjusting its length. O.S has a great page explaining what tuned pipes are and how do they work.

Glow engines designed for ducted fans are made a little differently. Take a look at the above OS .46 VX-DF engine. Notice how the carburetor is in the rear of the engine instead of being in the front. The exhaust is also in the rear.

The carburetor is moved to make room for the front of the engine to fit into the fan duct. The exhaust port is in the back so the tuned pipe can run straight back so that the entire GDF unit will fit nicely inside the fuselage.

Examples of GDF Installations

The aircraft below is a Balsa USA Enforcer (GDF) RC ducted fan jet with an O.S. 91 DF large head glow engine used in conjunction with a Byro-jet fan package.

Notice how the engine faces the rear of the jet. This is a called a pusher fan set-up. Most ducted fans are tractor fans, meaning the engine faces the front of the plane and pulls the are over the engine.

Tractor fans are more efficient because the suction end of the fan is not restricted by the engine. Tractor fans also do a better job of cooling the engine since all the air is pulled across the engine.

But as you can see, pusher fans are also very common.

Above is a close up of this ducted fan installation. This fan is mounted on top of the aircraft with its own tube as opposed to being housed inside the fuselage.

Above an A-4 Skyhawk with a Byron ducted fan unit also powered by an O.S. 91 DF engine.

This is a close-up of the GDF fan unit installed in the fuselage of the Skyhawk. As you can see, it's a tight fit!

More RC Jet Related Pages...

Let’s Go Flying! |

|

5 Steps for Successful First Flight! When the RC bug bites, it bites hard! Control yourself my friend! Save yourself much time and money by following these five steps to success! |