Brushless RC Motors

Brushless RC motors along with better battery technology have turned this hobby on it's head in the past few years allowing electric models to perform just as well, and in many cases better, than their engine powered counterparts.

So what exactly are brushless motors? Why can't the same electronic speed controller work with both types of RC airplane motors? Why do brushless motors have three wires instead of two?

What's the difference between inrunner and outrunner brushless motors and which type would be best for your next radio controlled airplane?

If you're new to the hobby it's easy to get confused with all this lingo, but as you're about to find out it's actually fairly simple once you get the terminology down.

Brushed vs. Brushless RC Motors

To fully appreciate the advantages of a brushless RC motor, you need to have a basic understand of how motors work. "How Stuff Works" has an in depth explanation of how motors work, and the graphics in the section were taken from that article. Here is a quick summary of how a canned motor works.

How a Conventional (canned) DC Motor Works

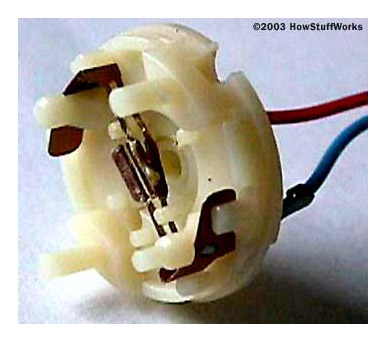

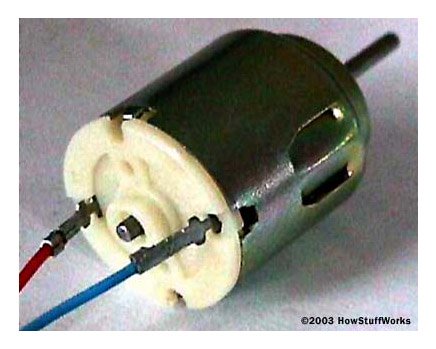

A conventional brushed motor is often referred as a canned motor. Every canned motor consists of the following parts:

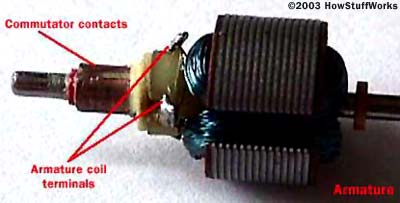

Armature- The rotating portion of the motor. It consists of the poles, terminals, and the commutator.

Poles- Copper wires wound around a piece of metal forming an electromagnet. The poles are attached to the armature. Most motors have 3 or more poles

Terminal- Point at which the copper wire of a poll attaches.

Commutator- A switch on the armature that reverses the current to the poles every 1/2 rotation so that the magnetic fields of each will always maintain rotation.

|

Brushes- Tabs in the motor cap that are wired to the battery and make contact with the plates on the commutator as the armature rotates.

Magnets- The outer shell (or can) of the motor is lined with two permanent magnets, of opposite polarity. This non-rotating portion of the motor is also referred as the motor stator.  The battery is wired directly to the brushes. The brushes make contact with the plates of the commutator as the motor turns. There are the same number of plates on the commutator as there are poles on the armature. When the brushes come in contact with the appropriate plates of the commutator, a particular pole (electromagnet) is charged. When a pole is charged, it is attracted to one of the magnets in the can and repelled by the other. |

The commutator acts as a switch by switching the polarity of each pole every time the pole passes a magnet. When the polarity is switched, the pole is attracted to the next magnet in the can while being repelled by the one it just passed. This process repeats as long as power is supplied to the motor.

Disadvantages of Brushed Motors

- The brushes and commutator wear out

- The brushes and commutator must be cleaned periodically

- Friction from the brushes slow the motor down

- Friction from the brushes lead to shorter flight times and battery life.

- Friction from the brushes cause lower power to weight ratio

How a Brushless Motor Works

Brushless RC Motors work on the same principle as brushed motors, except the electromagnets(poles) are stationary and the permanent magnets are on the spinning portion of the motor.

Since the electromagnets are stationary, there is no need for brushes! ESC's for brushless rc motors take care of switching the voltage of these electromagnets.

It's important to know that a brushless speed controller and a brushed speed controller can not be used interchangeably. They perform completely different tasks.

The quickest way to tell the difference between a canned motor and a brushless motor is to count the number of wire leads. All Brushless RC Motors have 3 wires. Canned motors have 2 wires. The third wire is used for feedback during the instant that it's not energized. Switching any two of these wires will change the rotation of the motor.

Advantages of Brushless Motors

- No brushes or commutator wear out

- Don't have to worry about cleaning the brushes or commutator.

- There's no Friction from brushes to slow the motor down.

- Longer flight times and extended battery life due to the absence of friction from brushes.

- Much higher power to weight ratio!

Inrunners vs Outrunners

There are two types of Brushless RC motors, inrunners and outrunners.

|

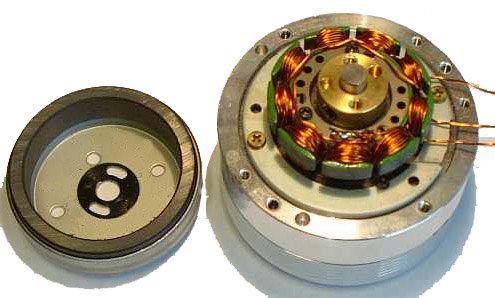

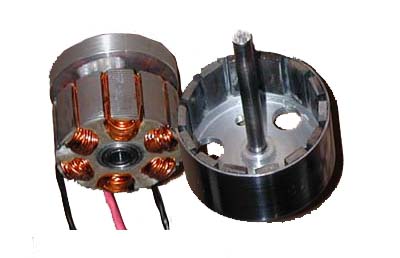

The permanent magnets of inrunner brushless motors are positioned on the inside of the electromagnets. Inrunner brushless motors are set up very similar to the canned motor explained above, except the permanent magnets and electromagnets are in opposite positions. |

|

|

An outrunner brushless motor has the permanent magnets on the outside of the electromagnets. You can see in the picture to the right that the outer hub holding the permanent magnets has the output shaft attached in the center. |

|

So which one is better?

The faster a motor spins, the more efficient it is. Inrunner motors turn very fast and are much more efficient than outrunner motors. Inrunner Brushless RC Motors require a speed reducing gearbox between the motor and propeller of your RC airplane.

For this reason, the output speed and torque of the propeller can easily be "tweaked" to facilitate different flying characteristics by using different size gears.

The downside of an inrunner is the added parts that can and do fail. The gears get stripped, and the gearbox shafts are easily bent. It can also be an obstacle when mounting the gearbox motor combination for your RC airplane neatly, especially under a cowling.

Outrunners

|

Inrunners

|

Popular Brands

Below is a working list of some of the more common brushless RC motor manufactures. At the bottom of each listing, there is a comments section for sharing your thoughts, experiences, or questions with each of these brands.

It seems like every day there is a new brand of brushless motor hitting the market. If you have experience with another quality manufacturer of brushless airplane motors,

Working List of Popular Brushless RC Motor Manufacturers

Feel free to ask questions or add comments!

KMS Brushless Motors

KMS Brushless RC Airplane motors and ESC's are made in Hong Kong China by Kinetic Motor Systems .

The performance and quality of KMS motors are comparable to ...

Emax Brushless Motors

Emax Brushless RC Airplane Motors are designed and manufactured by the Chinese company Yinyan Model Tech .

There are currently four different models of Emax ...

Electrifly Brushless Motors Electrifly Brushless RC Airplane Motors are top-of-the line quality motors. Electrifly is a division of Great Planes Great Planes Model Manufacturing, one of the ...

E-Flite Brushless RC Airplane Motors E-Flite has a solid reputation for being on the leading edge of electric powered flight technology. E-flite has a wide selection of electric RC airplanes ...

Related Pages

|

|

|

|

Home › Brushless RC Motors